Connector

Wholesale Connector Manufacturer

Goowell Electrical Co., Ltd is a leading manufacturer of connecting cables, mobile phone data cables, and Apple MFi-certified USB data cables. Our products include iPhone MFi Data Cable, Data Cable, Radio Control, Models Connecting Wire, Wiring Harness, Connecting Cable, UL Wire, Connector.

Why Choose Us

Wide Range of Applications

The company’s products are suitable for all types of electrical devices, including home appliances, medical equipment, new energy vehicles, and 3C-type digital products.

Advanced Equipment

The company has invested in state-of-the-art production equipment, including automatic terminal machines, soldering machines, and injection machines. The automatic terminal machines used by Goowell Electrical are designed for high-speed and efficient production of cables and wiring harnesses.

High Productivity

With its 8 production lines, around 200 workers, and a 20-person R&D team, the company is well-equipped to meet the demands of its customers and provide them with the latest and most advanced products on the market.

Leading Service

The company’s commitment to customer satisfaction is reflected in its comprehensive range of services, including 7/24 support before order, 100% inspection during production, and quality assurance for 1 year.

Definition of Connecting Cable

Connectors are parts or devices used for electrically connecting or disconnecting circuits etc. They can connect and disconnect by hands or with simple tools without requiring special tools or processes such as soldering.

Although there are various types of connectors, the large majority are one-piece types that are used alone or two-piece types consisting of a plug and socket. One-piece types directly connect printed circuit boards and wires to connectors.

Improve the Production Process

The connector simplifies the assembly process of electronic products. It also simplifies the mass production process;

Easy to Repair

If an electronic component fails, the failed component can be quickly replaced when an electrical connector is installed;

Easy to Upgrade

With the advancement of technology, components can be updated when electrical connectors are installed, and new and more complete components can be used to replace the old ones;

Improve Design Flexibility

The use of electrical connectors allows engineers to have greater flexibility when designing and integrating new products and when composing systems with components.

Keyed Connectors

These Connectors can be joined together when they are adequately aligned together. This property helps avoid accidental damage to the terminal pins of the Connectors.

ESD Shielded Connectors

The ESD Connectors have protection from electrostatic discharge, which can damage the circuit of its components.

Locked Connectors

These Connectors have an inbuilt locking mechanism which helps to keep the connection in place.

EMI Filtering

These Connectors have an additional feature that is mounted on the housing. This feature helps the Connector to shield itself from electromagnetic interference.

Water-Resistant Connectors

Water can damage Connectors very easily. Hence these Connectors are made water-resistant.

Hermetically Sealed Connectors

These Connectors can be used underwater. It will not get damaged by the water pressure.

Moisture/Oil Resistant Connectors

These Connectors are specifically made to protect them from oil and moisture.

Applications of Connector

Automotive Industry

Reliable electrical connectors are critical in vehicles, connecting various electrical systems such as engine control units, sensors, and communication networks. The automotive industry demands connectors with robust environmental resistance, preventing failures caused by temperature fluctuations, vibrations, and exposure to chemicals.

Aerospace Industry

In the aerospace sector, reliable connectors are vital for the safe and uninterrupted operation of mission-critical equipment and systems. Connectors used in aerospace applications must meet stringent standards for durability, electrical performance, and resistance to extreme temperatures, shock, and vibration.

Telecommunications Industry

With the increasing demand for faster and more reliable communication networks, dependable electrical connectors are crucial in the telecommunications industry. Connectors used in fiber optic cables and high-speed data transmission must offer low insertion loss, high bandwidth, and strong mechanical stability to ensure efficient data transfer and network performance.

Industrial Applications

In industrial settings, reliable electrical connectors play a fundamental role in powering and controlling machinery and equipment. Connectors used in industrial applications must withstand heavy-duty operations, while ensuring secure and stable connections to prevent downtime and optimize productivity.

Components of Connector

Shell

The electrical connector shell refers to the housing, nut, and tail attachment of the plug and socket. The role of the shell is to protect the internal parts of the insulators and contact bodies from damage. The positioning keyway is for the plug and the socket, and the nuts are used to connect and disconnect the socket. The tail attachment is used to protect the connection point of the wire and the contact body from damage and also used to fix the cable.

The shell also has a certain electromagnetic shielding effect. It is generally made of aluminum alloy through machining, cold extrusion, die casting. Steel shells are mostly used for glass sealing and high-temperature resistant electrical connectors.

Insulator

The insulator consists of a pin insulator, jack insulator, interface seal body, and line seal body, etc. It is used to keep the pin and jack at the set position and create electrical insulation among each contact body and between the contact body and the shell. The interface seal body and line seal body are added to the insulator to improve the environmental resistance of the electrical connector.

In order to achieve high-temperature and low-temperature resistance, flame retardancy, and ensure the stability of the geometric dimensions of parts, most insulators are molded from thermoset plastic, and the interface seal body and the line seal body are molded from silicone rubber.

Contact Body

The contact body includes a male contact piece and a female contact piece sometimes called a pin and a jack. And the connection methods are divided into the welding type, the crimping type, the press-in type, and the winding type, etc., to realize circuit connection.

The pin and the jack are the key component of the electrical connector, which directly affects reliability. Most of the pin and jack are machined from elastic copper alloy materials with good conductivity, and the surface is silver-plated or gold-plated to achieve low contact resistance and anti-corrosion. Generally, there are slotted jack, wire spring jack, crown spring jack, and punched jack.

Brass

Brass is the cheapest metal you can use in terms of weight. Generally, the zinc content in brass can range between 5% to 40% based on the application. Brass offers considerable strength, good spring and adequate electrical properties.

Brass connectors are mainly used for KK terminals.

Phosphor Bronze

Phosphor bronze is tough and offers increased strength compared to brass. It comes with impressive conductibility and superior fatigue resistance. Phosphor bronze also has excellent elasticity making it suitable for use in electrical contact springs.

Beryllium Copper

Beryllium copper is the best type of copper alloy for spring terminals. It contains around 0.5% to 3% beryllium with other elements. The alloy offers high strength and is cheaper than phosphor bronze.

High Copper Alloy

High copper alloys contain a high percentage of copper (more than 96%) and are suitable for demanding applications. The alloys have high strength coupled with excellent thermal and electrical properties. You can also use them in high-temperature settings as they don’t soften easily.

Regular Inspections

Regularly inspect your connector for signs of damage or wear, such as cracks or breaks in the housing. Ensure all contacts are secure and undamaged Check to see if the over-molding is working to protect your connection system as it was intended (e.g. water resistant).

Cleaning

Establish a cleaning schedule to remove any accumulated dirt, dust, or debris is important. Use a soft-bristled brush or a lint-free cloth for this purpose, and avoid using abrasive cleaners or solvents that could potentially harm the connector.

Protection

Protect your connector from moisture and other environmental elements that could cause corrosion or damage. When not in use, store your connector in a dry, cool place and use protective caps.

Environmental Protection

Depending on your electrical project, the connection may require additional environmental protection from external factors. For example, harsh environments can expose connectors to extreme weather. So, it is important to look for electrical connectors that can create the type of seal you need for your circuit.

Whether you are looking for weatherproof, waterproof, or UV resilient, these considerations will influence the choice of your connectors. Typically, heat shrink wire connectors and heat shrink connector kits are preferred for their environmental protection features, keeping rain, wind, and more at bay.

Durability

Electrical connectors must be resistant. If they are part of a permanent circuit, they need to be able to remain in place even when exposed to some tugging, stretching, or any other external pressure.

Here again, the focus is on working with electrical connectors that can guarantee a tight and secure connection designed for long-term usage. This is where heat shrink connectors can elevate your installation.

Ease of Installation

Essentially, electrical connectors need to be easy to use. The last thing you need during an electrical project is to waste precious time and effort establishing a connection between two different electrical parts. You want to be able to set up a quick connection without needing cable ties to hold your installation.

Our Factory

The large workforce at Goowell Electrical allows the company to efficiently manage its production processes and meet customer demands. The experienced workers are trained to use the latest technology and equipment to produce high-quality products that meet the strictest standards for quality and reliability.

Our Service

The company’s 7/24 support before ordering ensures that customers receive the information and assistance they need to make informed purchasing decisions.

Whether you have questions about product specifications or need help with an order, Goowell Electrical’s customer service team is available to provide support and answer any questions you may have.

The company’s 100% inspection during production ensures that each and every product is thoroughly tested and inspected before it is shipped to customers.

Goowell Electrical also provides quality assurance for 1 year, giving customers the peace of mind that comes from knowing that their products are backed by a commitment to quality and reliability.

Our Certificate

The company has obtained a number of certifications that demonstrate its commitment to excellence, including ISO 9001, Apple MFi, High-Tech Enterprise, UL/CE/FCC/ROHS, and others.

Contact Us

Frequently Asked Questions

Q: What are Application of Connectors?

Q: What are the connection methods of electrical connector?

Q: What are different types of connectors?

Q: What types of electrical connectors are there?

Q: What types of plug connectors are there?

Q: What does an electrical connector consist of?

Q: What are the advantages of direct plug-in electrical connector?

Q: What factors should be considered when choosing an electrical connector?

Q: What is the benefit of using a joint connector?

Q: What are electrical connectors made of?

Q: How do you remove pins from electrical connectors?

Q: What are the essential features of connectors?

Q: What factors should be considered when purchasing an electrical connector?

We're well-known as one of the leading connector manufacturers in China. If you're going to buy or wholesale high quality connector for sale, welcome to get quotation and free sample from our factory. Also, customized service is available.

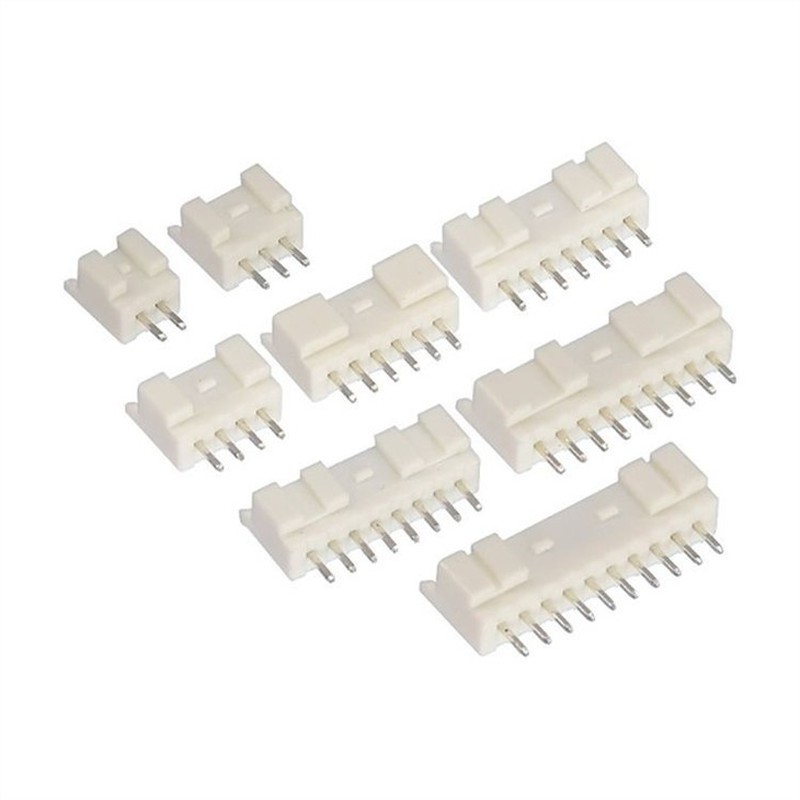

Customized 2mm Pitch Female Connector, 2mm Pitch Female Connector